Computer Aided Manufacturing

C.A.M. design, developed by LGA Engineering, allows us to assist clients in the project optimisation phase, as well as in the product creation or construction phase. C.A.M. design is applied across various structural disciplines and for different building materials.

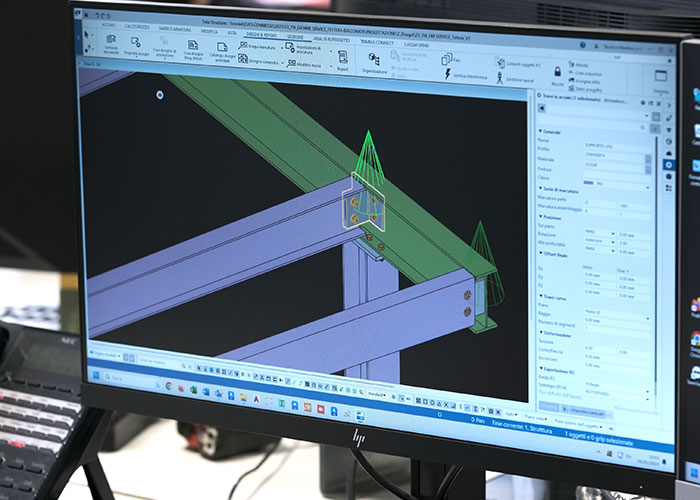

C.A.M. stands for Computer Aided Manufacturing. C.A.M. design uses numeric control software applications to create detailed instructions which machines needs for parts processing. With the C.A.M. methodology, a plan is defined for the equipment design and machine programming. C.A.M. systems make it possible to use a wide range of production equipment and integrate the management of the product life cycle, ensuring the use of standard resources and correct data. In the first phase of the design, the initial design of the product is created based on the customer’s needs. This stage is carried out using design software and the engineers and designers design the product by creating a three-dimensional model. Using parametric modelling, the designer can make the model complete with all the necessary information, extract the lists of material, and obtain the tables required by operators.

Once the design phase is complete, it is necessary to use machinery equipped with C.A.M. software and controlled by specialist operators. At this point, the operator will decide which processes the machine will have to follow in order to create the designed object. Lastly, with the lists of materials, the purchasing office will be able to proceed with the purchase of the materials needed to make the product. This process makes it possible to directly connect design and production without the need for intermediate stages that could generate errors or misunderstandings.

Nesting is a process that makes it possible to efficiently position multiple shapes on a specific surface area. Raw materials and sheet metal materials are expensive and can generate waste in industrial cutting. Therefore, the best solution is to create nesting structures to group together as many parts as possible to be cut on the same sheet metal. This process, which is made possible by the C.A.M. methodology, maximises the use of the machines, reduces waste, and lowers the costs of the material used to a minimum. The nesting system is a numerical control programming tool in which component models generated by parametric software are used to generate the codes needed to operate computer numerical control machines. This methodology makes it possible to simplify the workflow from the cutting workshop to inventory management.